Fluid Borne

Stainless Steel Connectors

Our complete line of stainless steel vibration control products includes vee assemblies, flexible hoses, expansion joints, bellows pump connectors, expansion compensators, housed expansion joints, piping guides and ball joints.

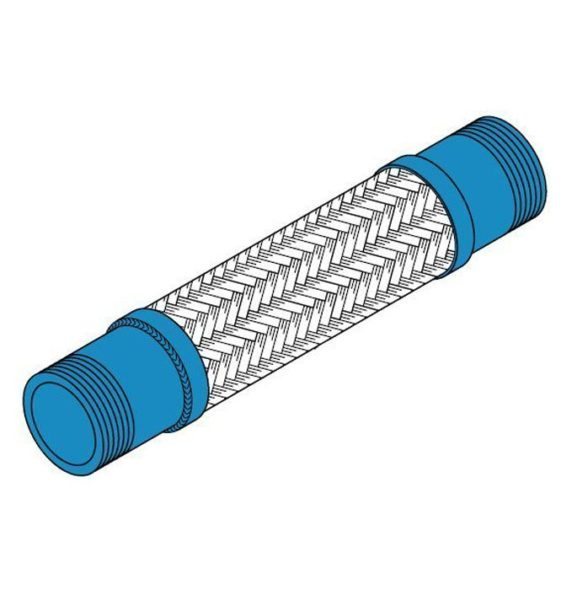

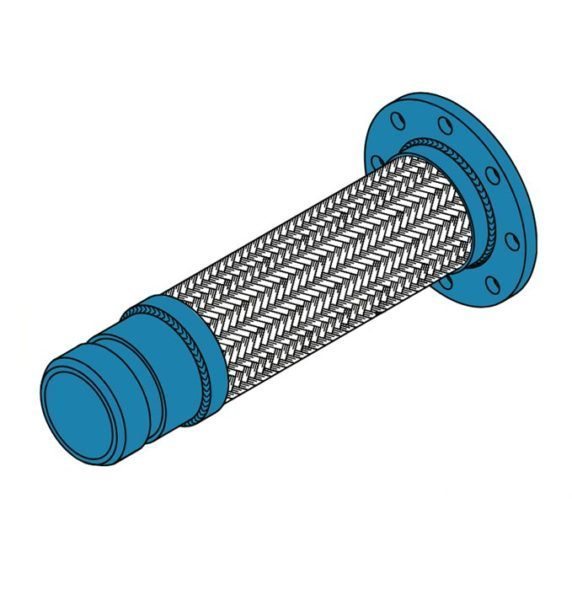

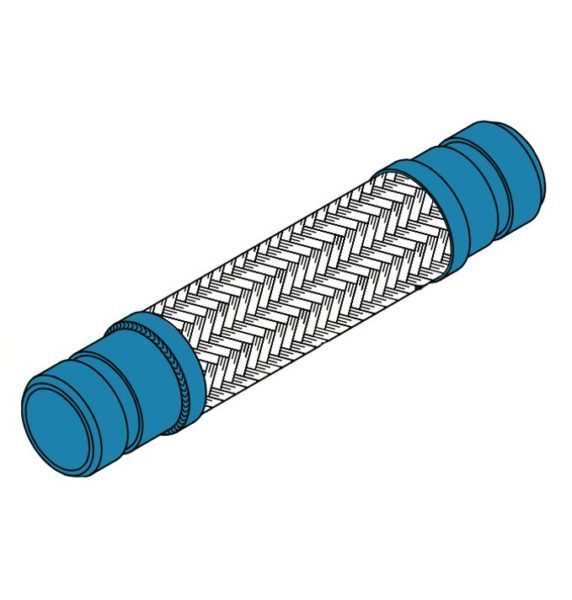

Flexible Hoses

Our stainless steel flexible connectors are designed for both high and low temperature conditions, as well as high pressure and full vacuum applications in piping systems. Stock sizes include 1/2” (13mm) through 16” (400mm) pipe diameter, while temperature ranges are from below 0°F (-18°C) to 850°F (454°C) when using our standard 304 stainless steel. Double braid construction for higher pressures or braid-less construction for low pressure venting or exhaust applications are also available.

Vee Assemblies

Our unique Vee assembles are designed to handle all types of seismic motion, with construction based on two 30, 60, 90 triangles complementing one another to form a 60° “Vee” at the bottom. To accommodate unusual angles, our Vee assembles feature floating ASA 150 carbon steel flanges at both ends—a truly unique feature in our industry.

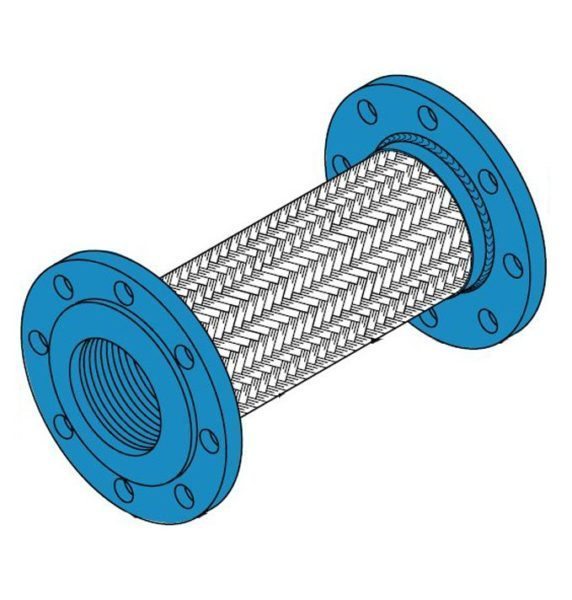

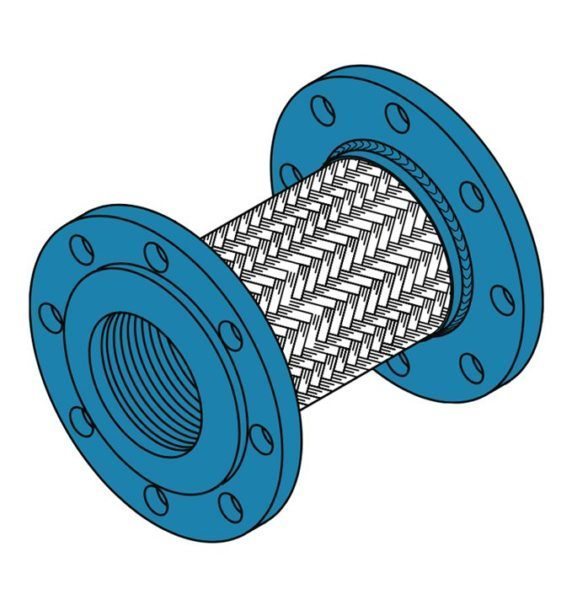

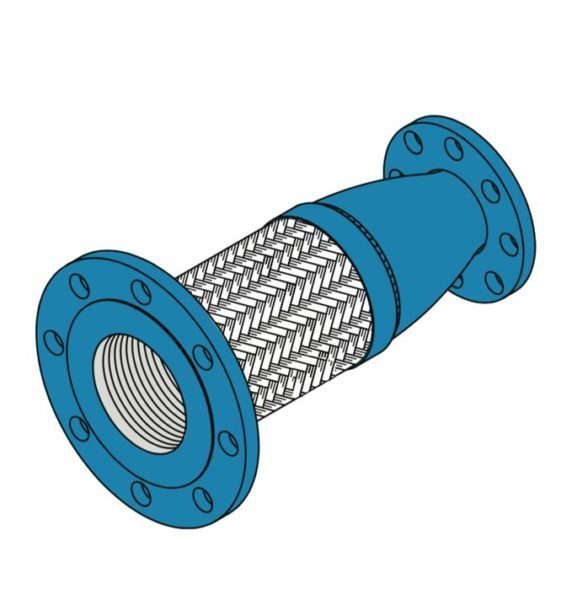

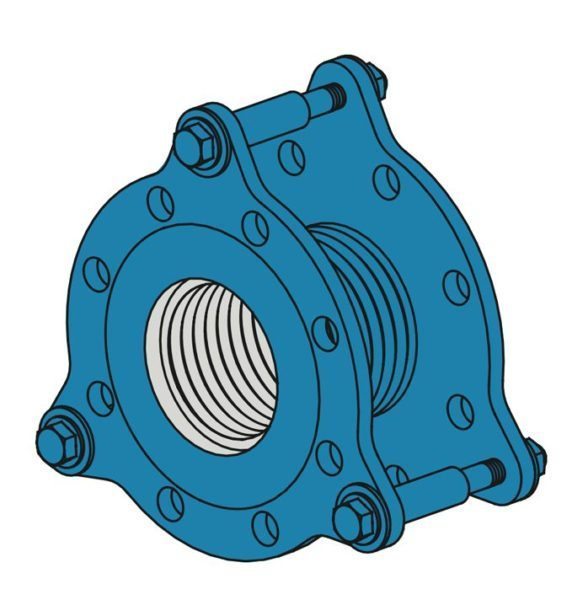

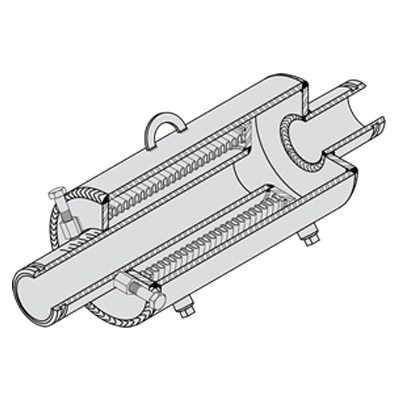

Expansion Joints

Our expansion joints are available in a wide range of configurations and designs to accommodate different operating pressures and required movements. Joints can be customized to your specific product description based on project specifications.

We also stock expansion joints in 2” to 16” diameters with 2” axial and 1/4” transverse capability.

Bellows Pump Connectors

Our bellows are deeper and wider than most comparable products available on the market, and are constructed of heavier material to handle operating pressures without braid. The product should be used when a combination of short length with greater movement capabilities along with the other benefits of stainless steel (high temperature and pressure) are required.

We also stock expansion joints in 2” to 16” diameters with 2” axial and 1/4” transverse capability.

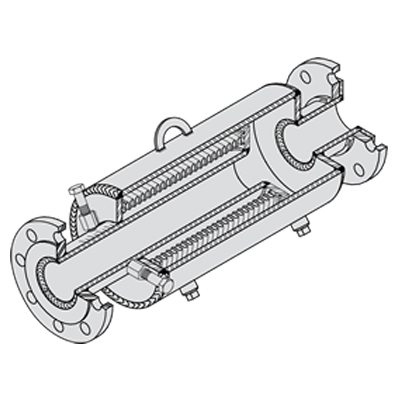

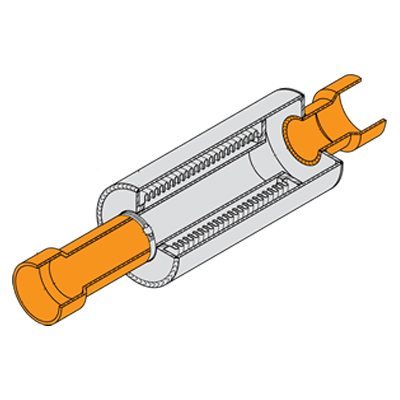

Expansion Compensators

While the industry typically produces two styles of expansion compensators and housed expansion joints, one of which is referred to as “internally” and the other “externally pressurized,” we favour the latter version due to the enhanced bellows stability. The components are furnished with a Fixed ASA150 Drilling Raised Face Carbon Steel Flange on the one end and a Floating Flange on the other.

We offer three movement choices: 2” (50mm) compression and 1/2” (13mm) extension, 4” (100mm) compression and 3/4” (19mm) extension or 8” (200mm) compression and 11/2” (38mm) extension. All are designed for use in hot-running systems.

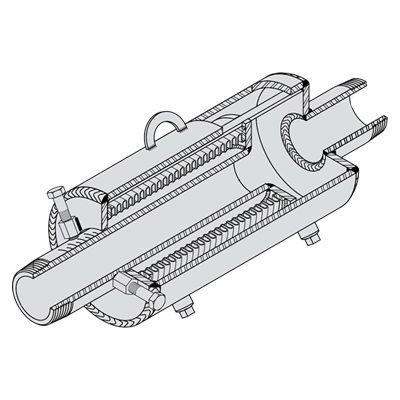

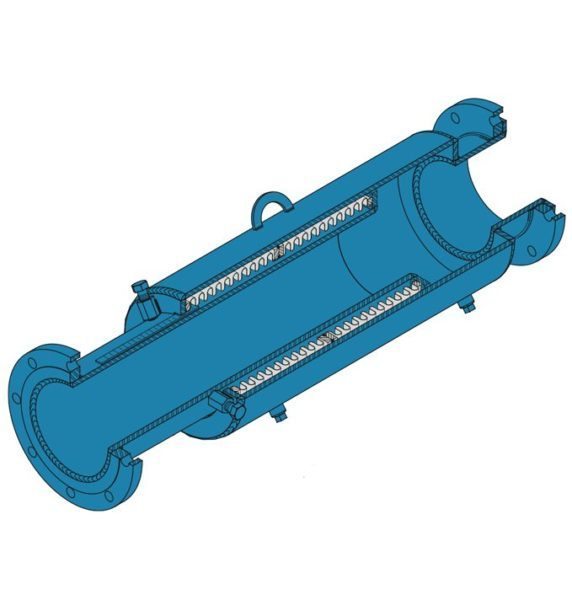

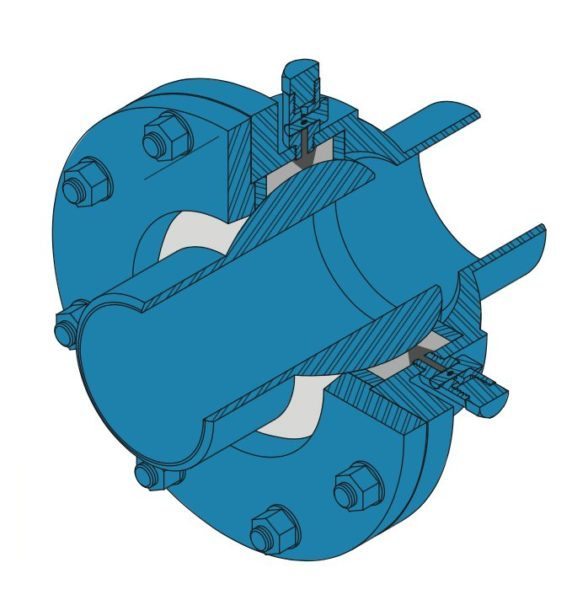

Housed Expansion Joints

Our housed expansion joints are effectively a bellows protected by and guided within a pipe housing. They are furnished with a fixed ASA150 drilling raised face carbon steel flange on the one end and a floating flange on the other. The alternates are carbon steel threaded nipples, weld or grooved ends or copper female sweat ends.

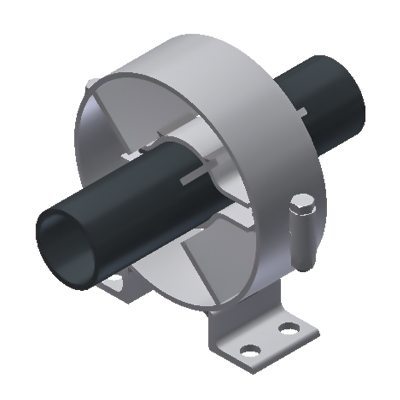

Piping Guides

Our adjustable sliding guides offer several key benefits including a single size guide for all thicknesses of insulation, less friction with our stainless steel slides, sturdier construction and the ability to use the guides as load supports. All of our anchors are manufactured to order.

Ball Joints

We supply flanged and weld end ball joints, while also offering fully custom-engineered systems in cases where clients lack specifications or where specifications require design by the vendor.

Let's talk about your project needs

We offer a full suite of vibration control products and engineering services.

Contact a member of the Octave3 team today to learn how our turnkey and agile service process is designed to address the full scope of your vibration-control requirements.

Octave3

(905) 844-5020 ext. 812